As medical devices demand higher performance, repeated sterilization, and compact form factors, ensuring long-lasting connectors has become increasingly critical. Effective design strategies focus on selecting the right materials, implementing robust sealing solutions, and validating performance through rigorous testing. This article explores these approaches, explaining how materials, seals, and systematic validation extend connector lifetime and maintain reliable performance in demanding clinical environments.

Key Approaches to Maximize Medical Connector Lifetime

Materials: Pick The Right Polymer Or Metal For The Job

For repeated autoclave: PEEK and certain polysulfones (PPSU/PSU) retain mechanical properties across cycles and are frequently used in reusable medical components. Material data and finished-part sterilization testing are required to verify performance.

For cost-sensitive single-use: medical-grade polycarbonate and lower-grade plastics can be used if the part is intended for limited cycles or disposability.

Seals & Hermeticization: When Environmental Protection Is Necessary

When devices operate under repeated thermal cycling or pressure differentials (or will be autoclaved often), hermetic glass-to-metal seals are a proven technique to protect contacts and electronics for thousands of cycles. They are a higher-cost solution, but their longevity and low leak-rates suit implants, high-pressure devices and applications where ingress means mission failure.

Validation & Testing: Ensuring Connector Performance

- Mating-cycle + contact resistance tracking: provide the resistance curve (ohms) across cycles, not just a single rating.

- Sterilization cycle test reports: show before/after mechanical and electrical property data for the actual assembly.

- Helium leak / hermetic tests: required for true hermetic feedthrough claims.

Design Collaboration With OEM/ODM Suppliers

Achieving long-lasting medical connectors goes beyond selecting the right materials and seals — close collaboration with experienced OEM and ODM suppliers is critical. These partners can:

- Engage Early in the Design Phase: By participating from the concept stage, suppliers help identify potential failure modes and propose design modifications before costly mistakes occur.

- Provide Tooling, Molding, and Rapid Prototyping: Suppliers can optimize mold design, perform pre-production tests, and deliver quick sample iterations to ensure manufacturability and performance.

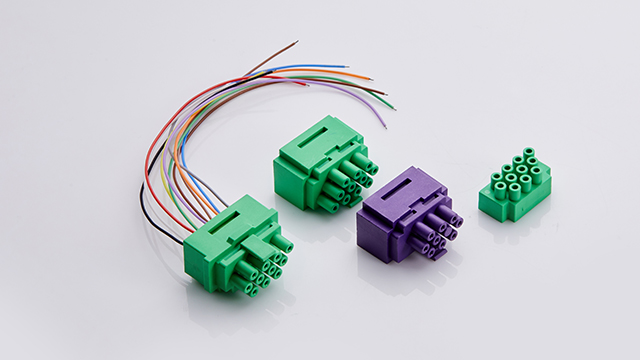

- Offer High-Density or Custom Cable Solutions: For complex assemblies, OEM/ODM partners can provide multi-pin, high-density connectors or integrated cable harnesses tailored to the device’s requirements.

- Support Full-System Validation: Working with device manufacturers, suppliers can verify connector performance within the complete system, reducing field maintenance issues and ensuring reliable long-term operation.

Partnering with suppliers in this way ensures that connectors are not only designed for current device requirements but are also future-proofed for repeated sterilization, mechanical stress, and evolving clinical demands.

Medical Connector Suppliers Demonstrating Industry Best Practices

- Amphenol — offers both off-the-shelf medical interconnects and cable-assembly services; positions itself to serve therapeutic and monitoring equipment with both standardized and custom solutions.

- KINSUN Industries Inc. — specializes in medical connectors, including hermetic and sealed solutions; provides glass-sealed feedthroughs and robust connector assemblies designed for long-term, leak-free performance in clinical applications.

- TE Connectivity — broad portfolio across high-pin count and shielded connectors; offers medical engineering services to match connector performance to device needs.

- Cambus Corporation — a Taiwan-based OEM/ODM partner providing custom injection molding, connector assembly and cable assemblies; typical partners use firms like Cambus for tailored designs where small-run customization, tooling and cable integration are required.

Integrating Design, Testing, and Supplier Expertise for Longevity

Long-term performance of medical connectors relies on careful upfront design choices, thorough validation protocols, and collaboration with experienced OEM/ODM partners. By selecting the right materials, optimizing contact metallurgy, implementing robust sealing strategies, and verifying performance through rigorous testing, device manufacturers can minimize failure risks and ensure reliable operation in demanding clinical environments. Partnering with knowledgeable suppliers also allows for tailored solutions, from high-speed connectors to hermetic feedthroughs and custom cable assemblies, ultimately supporting both patient safety and device longevity.